Vision

Construction of one of the worlds first hydrogen-powered aircrafts

Innovative and future-oriented solutions to current problems

Emission-free aviation

Current aim

Development of a prototype of a hydrogen powertrain

Testing and evaluation of the system

Collecting data for next projects

Our system

With over 30 sensors and another 30 active or passive components, a fuel cell system is a complex challenge for our team. This is where advanced control technology, thermodynamics and fluiddynamics meet. Due to the very specific requirements of a fuel cell, it is important to always operate the system at its optimal points.

Some of the most important components are described below:

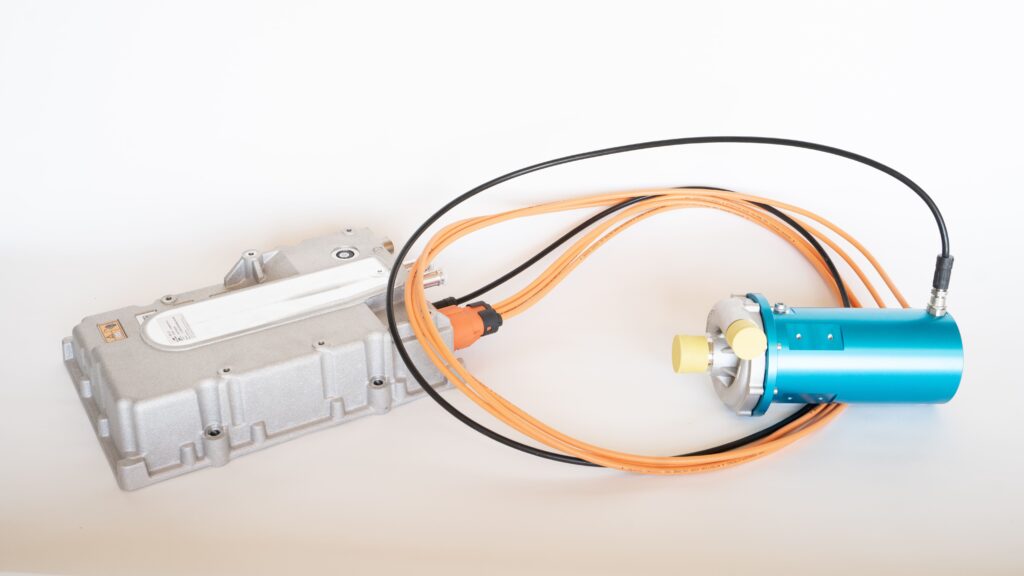

Compressor with inverter

With a powerful compressor and a backpressure valve, the air is brought to the desired pressure before the fuel cell. The inverter supplies the compressor with the necessare high-voltage power.

Air filter and hoses

An air filter is used to protect the fuel cell from pollutants. The air piping consists of flexible hoses, which, depending on the mechanical connections of the components, must be completed with transition parts. The hoses are attached to the components with hose clamps.

Sensors

Over 30 sensors monitor and control our system in order to record or further process all measurement variables. Precise sensor data is also required for the complex control of the system. The measured variables include pressure, temperature, mass flow, humidity and conductivity.

Cooling pumps

Due to the low efficiency of fuel cells, almost half of the energy in hydrogen is converted into heat. Therefore, our system has to be cooled by a pump and an efficient heat exchanger. Depending on the required cooling capacity, the pump can be operated at the optimal control point.

Software and controls

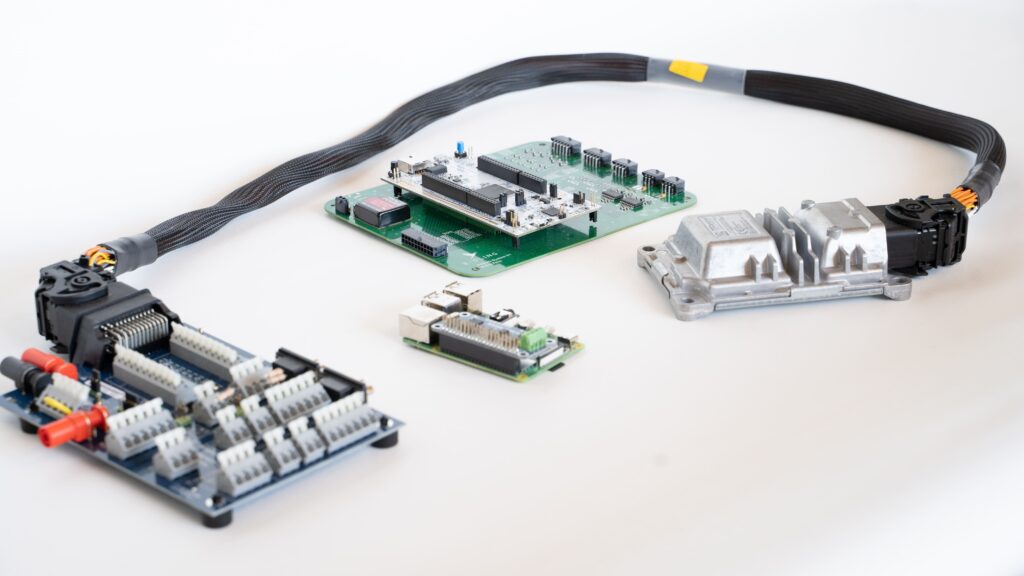

A self-designed main control unit, together with an extension module and a Raspberry Pi, takes over the measurement, storage and further processing of the sensor data. Almost 20 different actuators are controlled on the main control unit. All the data can be displayed in various diagrams and monitored at any time via web interface.

Projektverlauf

Although many sensors and other components are still stuck somewhere between production and delivery, we were able to carry out some tests on May 5, for example, to control the cooling pump with different signals. Further tests will follow in the course of the next few weeks.

On a sunny spring morning, we set up our metal scaffolding for the test bench outside in front of the hangar. With the help of the aluminum profiles and the groove plates from Item, we will be able to attach all components directly and will still be very flexible.

In the longer period between the exam phase in February and Review 3, we have made great progress. The current status is that all components have been ordered in the hangar and that we will soon be ready to carry out the first tests. Our main occupation will now be the software and the regulation.

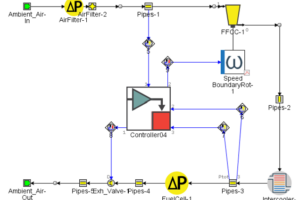

The sensitive membrane of the fuel cell requires very precise values of temperature, mass flow and pressure of the air and hydrogen in the fuel cell. To obtain these values, we created a digital twin on Gamma Technologies, which can later be used to design the various controllers using Simulink.

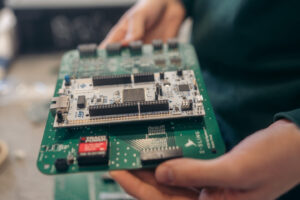

For the regulation and control of our system, we have decided to develop our own electronic control unit. We started to design a circuit board on a professional program and were finally able to send it to production after several weeks. Assembly and testing will follow in the near future.

One of our most important milestones was the complete assembly of our system which has to be as compact as possible. Although the system is not yet installed in an aircraft, it is still important to us to make the whole thing as small as possible. After several challenging and time-consuming iterations, we are happy with the result.

Also in Review 2 we were able to bring the viewers up to date with the current status of the project. Since the last review, both modules have gained many new insights and have been able to achieve further theoretical and practical progress on the aircraft and the fuel cell system. More information can be found in the related blog post.

We are proud to announce that the Swiss company EH-Group, which has its base in Nyon, has entered into a partnership with us. The young company produces fuel cells and also develops complete systems. In this way, they can support us with their knowledge in our project in the best way possible.

On Friday morning, November 5, Review 1 of the new e-Sling project took place. The two modules, hydrogen and aircraft, had to present their progress over the past few months in a 20-minute presentation. Afterwards, questions were asked by all those present. The presentations will incorporate into the final grade of the focus project.

For two days, a group of focus students from e-Sling visited the Hydrogen Expo in Bremen. They were able to make important contacts and find some support from larger industrial partners.

More than 200 people attended the RollOut of the e-Sling Team 2020/21. Among them were sponsors, patrons, family members, team members and supporters. In addition to the big unveiling of the aircraft, dominic Gisin's speech and the flight raffle were definitely a highlight.

Already on the first day of the new semester we sat together as a new focus team and had our first session. Tasks were assigned, goals were formulated and initial strategies were explained. The first contacts were already made and we started to feel comfortable in the team!